Recommendations for Glider check at LittleCloud's

Controlling your wings over time is an important step.

It aims to check that your wings are still able to fly correctly.

On the sticker is indicated the periodicity. The first of the 2 terms reached triggers the need for this control.

A suspect behaviour should also lead to control the glider.

You should know that even when not in use, your wings “work”.

Depending on the storage mode and its environment, this work is more or less important.

Remember that the fabrics (polyamide/nylon) and the lines (dyneema or kevlar) do not like heat or humidity, and even less when those two are combined.

Regarding the fabric:

A fabric offering at least 600gr of resistance to the Bettsometer test is considered to be compliant.

At the Porosity level: within ten seconds, the wing must be tested on the ground (inflation) and in flight to check that basic manoeuvres (collapse <50%, frontal <30%) do not cause parachutal phasing, and when it’s not stable (ie stay locked in parachutal), it should retain a speed range at the brake greater than 12km/h.

Only then, if the behaviour is not satisfying (deepstall stable), only then it can be reformed.

Be careful when estimating the lifespan of your wings based on the porosity measurement.

It should be noted that the evolution of this is not linear.

We have seen wings “rejuvenate” between two checks carried out by different centres!

It is necessary to favour the measurement on the leading edge (30% of the chord).

In terms of deformation, only flight tests will make it possible to qualify the validity of the wing for flight or not. Same manoeuvres as mentioned above will tell.

Concerning the fringes on the inter-box holes: if greater than 5cm, a flight test makes it possible to check that the structure is not deformed.

Regarding the lines:

Trim control is essential.

Checking the brake clearance is also essential!

However, we set a tolerance vis-à-vis the factory setting sheet.

An offset of 20 to 30mm between the As and the Cs is acceptable (angle of attack greater than the control sheet).

You should know that the tolerance in production is around 10mm per row.

The measurement is carried out under a load of 5 kg for the wedging checks

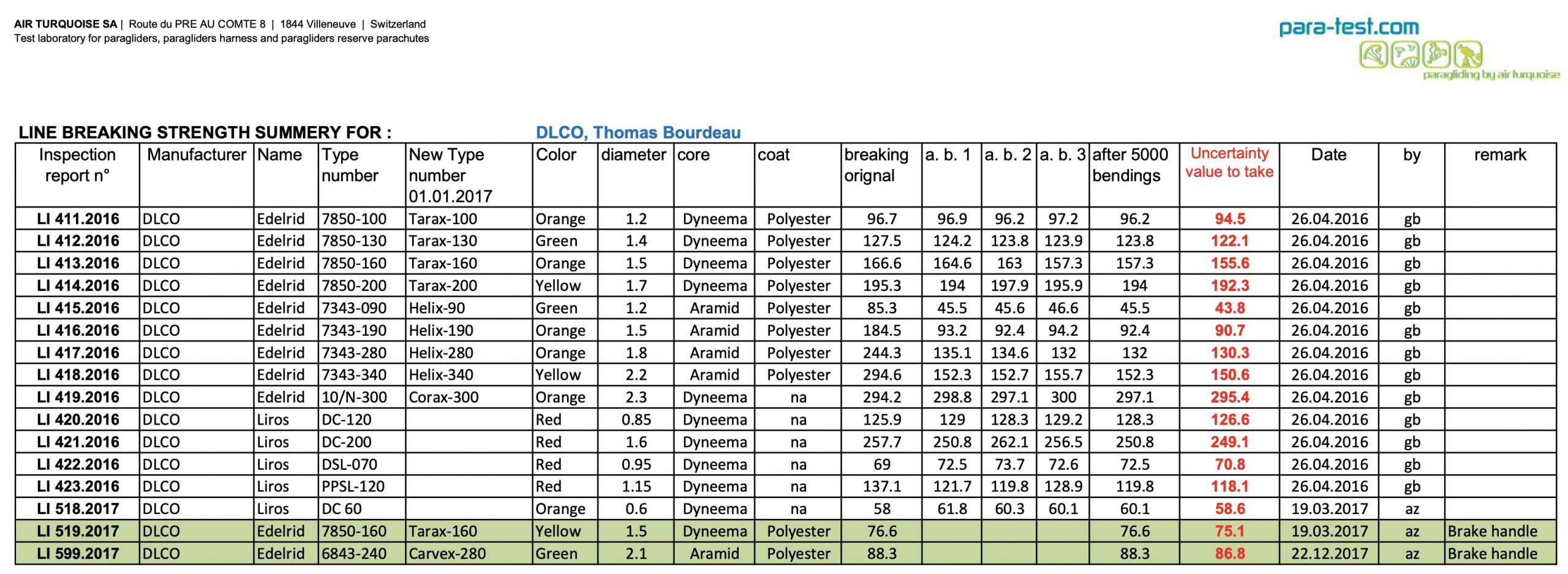

Regarding the lines resistance check:

It is forbidden to break the upper dyneema lines.

The load test and glider certification ask us to comply with a resistance of 14G on the sum of the lowers after “bending test” at the maximum load of the size (See on sticker).

The Bending test is here to simulate the ageing of the lines.

Therefore we can consider that a glide is not authorised to fly if the sum of its lowers resistance is less than 14G from the maximum all up weight.

In this case, we recommend to change the lowers.

In the event of a line replacement, they must be replaced symmetrically. A measurement on the symmetrical line is also a recommended solution to check its working condition over time.

Be aware that dyneema is working along all its life.

The triming plans and materials are here:

Others:

https://drive.google.com/open?id=1sSWP4f-WQnDVfD-TsS6yhBEG0o4J50b_